I have three more items to complete on the Cotton Brute and I have a maximum of 19 days to get them done. I want to have the locomotive ready to rock and roll for Old 97 Rail Days in Danville VA, which is happening on the weekend of September 23rd.

Those three items are: fabricating a new fuel tank end to replace one that has gotten lost over the years, hard wiring the trucks in such a way that the wires are not prone to breaking off, and installing DCC.

The trucks were picked to be first because the tank would be much easier to build if the slider pickup on the trucks were eliminated. I had previously tried to just solder a wire between the trucks and the contact pads on the frame, but the wires flexed so much at the solder joints that I feared they would break off eventually.

The trucks are an odd design. There are two geared axles (middle and outer) on each truck and one not geared (the inner wheelset). The dummy wheelset is made of a hideous gray plastic that looks nothing like steel, something that I resolved to take care of while I was there with a bit of steel colored paint. This will do for the outer face of the wheels, but unfortunately nothing can be done for the treads.

The two geared wheelsets have one wheel that is isolated from the axle. Power (actually ground since they are on the left side of the loco) is picked up on the non-isolated wheels and transferred through the axles to the metal body of the truck, which is then fastened both mechanically and electrically to the frame with a metal pin that also holds the truck and idler gear in place.

Power is picked up on the isolated wheels by way of a slider contact on the backside of the wheel. This contact is a single piece that runs along the bottom of the truck (isolated from the truck frame by a fiber insulator) to the inner end where a finger sticks out to touch a contact pad on the bottom of the locomotive. This finger is the part that had to be eliminated.

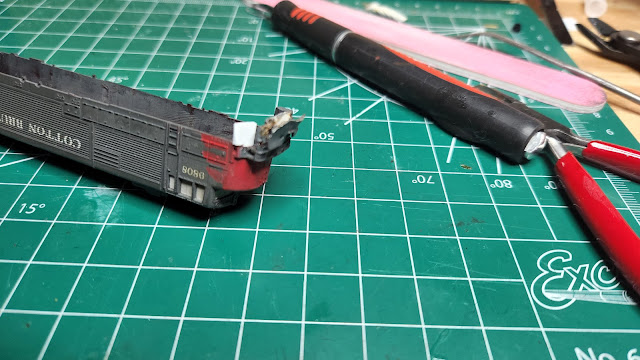

The front truck was done first. A hole was drilled in the truck frame and a channel hollowed out to clear the solder joint. Said solder joint affixed a power wire to the contact at the bottom of the truck through a hole in the insulator. The wire fed up through the hole drilled in the truck frame to be attached to the locomotive.

Another hole was drilled in the locomotive frame (fortunately the original part of the U30CG frame, not the depleted uranium tank that joins the two ends) and the wire was fed up through it, leaving a loop between truck and frame to accommodate the truck swing. Once everything was in place a continuity check was done to ensure that the power wire was fully isolated from the frame and that the truck wheels were connected.

After that the finger was removed and once again the entire circuit was checked for continuity where needed and insulation where not. Once this was successfully tested on the front truck, the rear truck was likewise modified. And with that done, it was time to fabricate the tank end.

The tank end was going to be a challenge because on the Minitrix U30CG that was the donor locomotive there is an air tank affixed to the end..sort of. The only parts of the tank that are actually present are the ends, there is no middle of the tank. This allows the trucks enough room to swing while appearing to be close enough to eliminate any unsightly gaps between the fuel tank and the truck end. This also served to disguise the slider contacts coming from the trucks, which have now been eliminated.

As I was looking through photos of the real-life U30CG however, I noticed that the air tanks were noticeably absent. Likewise, the U30C from whence the U30CG came also had no air tanks. In fact, the only place I found air tanks was on the Minitrix model.

This, of course, made things somewhat easier. Since no air tank was required, I decided to extend the fuel tank end a bit to reach all the way to the end of the leading truck. The tank end was fabricated from sheet styrene and affixed to the leading end of the fuel tank, then painted Cotton Brute Grey. The existing rear tank (complete with fake air tank) was left alone.

With trucks and tanks out of the way, the next step was installing a DCC decoder. At first the plan was to install a simple Digitrax DZ126 decoder, for which there was plenty of room once the weight above the motor was removed. The idea was to get the locomotive chipped and then think about perhaps installing sound at a later date. But, it was reasoned, why do the work twice?

An ESU Loksound 5 Micro and two speakers were obtained and the decoder loaded with U50 sound files (fun fact, Jim Fitzgerald referred to the Cotton Brute as a U60CG). They were then delivered to me for installation.

At first I had thought that I could simply install the sound decoder above the motor in the same manner that the DZ126 installation was planned, but sadly it is just a bit too tall to fit between the motor and the shell. There is a lot of room under that shell but it is taken up by 11 ounces of cast lead weight. Some of that weight would therefore have to be sacrificed to fit the decoder and speaker.

I picked the locations to coincide with weights that could be completely removed and replaced with styrene shelves to hold the components, but when I weight the removed weights I found they totaled 4 ounces, a full quarter pound. The locomotive initially weighed in at 24 ounces (that's a pound and a half) so with the 4 ounces gone it would still be a hefty 20 ounces, but I really didn't want to cut a full sixth of the locomotives weight out.

On the other hand, I didn't want to destroy the weights that had been so carefully cast by the locomotives creator, but after thinking about it for a while I decided that the locomotive was unlikely to be converted back to DC once the sound decoder was installed. So, the weights were marked and the cutting began.

I would like to note for the record that all lead weight cutting, filing and shaping was done while wearing a respirator mask, goggles and gloves and my hands were thoroughly washed after each evolution. Furthermore, during the cutting and filing processes a shop vac nozzle was duct taped to the vise to remove the dust. The shop vac that I used is the type that can be fitted with a bag, and one was fitted so that the lead dust could be properly disposed of. Always use caution when working around toxic substances like lead.

In all, a total of 1.3 ounces was removed from the two weights to clear enough room for the decoder and the speaker. A channel was also cut along the tops of the remaining weights for the decoder wires, probably another couple of tenths of an ounce. I will install the decoder and then test it with each of the speakers to determine which speaker sounds best. I had considered installing both speakers, one forward and one aft, but I decided I really didn't want to remove any more weight.

This is where the first major snag was encountered. While ensuring enough room had been made for both decoder and speaker I realized that the decoder doesn't have long enough wires to reach the speaker or rear lights. This is a long locomotive. So now I am on hold until the decoder wire I have ordered comes in.

Two out of three items taken care of means that it was still a pretty productive weekend.