The restoration continues.

I took no photos of the truck removal, disassembly and cleaning but it has been done. The hard-wiring has not been completed, but the coupler has been installed on the rear truck. Micro-Trains has a coupler conversion for the Mini-Trix U30CG locomotive that served as the donor for the original build, so this was not a difficult operation. The front coupler has not been installed since that would take a complete rebuild, and possible removal, of the snowplow, and since the original build did not have one this was not a difficult decision to make. Perhaps a front coupler will be installed at a later date, but for now the rear coupler is all that it needs.

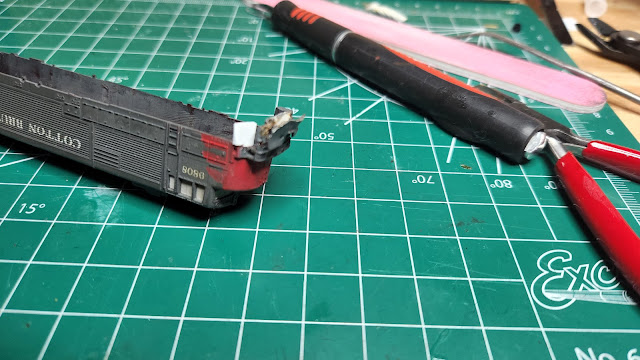

With the trucks and couplers done (but not hard wired, that is a project for another day) I turned my attention to the shell. Over the years the conductors side front step had been broken off, so something had to be done about that.

The first thing I did was file the broken area even with the bottom of the remaining step so that I would have a flat surface to build from. This made a notch from the bottom of the step to the body of the locomotive which required some fitting of the replacement piece.

A notch was cut in the piece of styrene that I was going to use for the replacement rear step support and it was carefully sanded and fitted to the broken surface. I didn't concern myself overly much with getting the width right because that would be taken care of later on.

The new step support was then glued into place and cut to the proper length.

The new bottom step was cut from a thinner piece of styrene and modeled after the engineers side bottom step. Once again I wasn't overly concerned with getting it exactly right since I was going to shape it once it was in place.

With the new pieces roughed in and glued in place, the hardest part of model railroading then began. I refer, of course, to the time it takes for the glue to dry.

Once the glue had dried sanding sticks were used to shape the replacement pieces. The rear step support is tapered from the top to the bottom, so it had to first be sanded flush with the locomotive body side and then the rear was sanded to the correct profile.

The inside of the bottom step and rear step support also had to be shaped with sanding sticks to ensure a proper fit to the chassis. I wasn't overly concerned with getting the inside shape exactly right because no one is going to see it once the shell is installed, but the outside was carefully shaped.

Two steps had to be cut and fit, then glued into place. I was careful to get the outsides right, but the insides are a little long. They will be trimmed off and the final shaping done when the glue dries.

And now, once again, we wait.

I have ordered a set of Gold Medal Models handrail stanchions, and once they arrive new handrails will be formed from brass wire and installed. After this is done the gray paint will be carefully matched, then the new steps, handrails, and the edge of the snowplow that is showing bare metal can be painted.

But that is a tale for another day.

No comments:

Post a Comment